Milos Sulphur Mine and Processing Plant

Introduction

The ruins of Milos Sulphur Mine, in the picturesque Paliorema bay on the Greek island of Milos, are remnants of an important period of industrial history on the island. Milos contains abundant mineral deposits of volcanic origin including sulphur, manganese, bentonite and perlite, all of which were, or continue to be, subject to industrial exploitation. Mining of Sulphur has long ceased to be economical in developed countries since abundant supplies are available as by-products of refining of sulphur-rich hydrocarbons. Pure sulphur is still extracted on a small scale at several volcanic sites such as Kawah Ijen in Indonesia, although this relies on low labour costs and the absence of the need for extraction processes from ores.

In its final years of operation, the sulphur processing plant employed the innovative Svoronos method for highly efficient recovery of sulphur from ore. This method was employed by the Milos Sulphur Mines S.A. from 1952 to 1958 until it went bankrupt following a massive drop in sulphur prices. Today the buildings are in a rather desolate state with most roofs missing, thus exposing the machinery, which largely remained in place, to the elements. Many smaller items have been removed, some to the local mining museum, whilst many others have been stolen as access to the site is not restricted.

|

Ruins of Svoronos process sulphur-processing plant |

Sulphur-processing plant viewed from beach |

Paliorema Bay with mine buildings |

Mine Ownership

Ownership of the Milos sulphur mines passed through a succession of companies. The first Greek mining concession of any kind was issued to Vassilios Melas on 11.05.1862, largely relating to the Paliorema site, and Sulphur was extracted in the following years. The mine was sold to Michael and Victor Melas in 1877, who in turn sold it in 1880 to the Municipal and Public Works Co. S.A. (Α.Ε. Δημοσίων και Δημοτικών Εργων) . This company was absorbed into Mines and Public Works Co. S.A. (Α.Ε. Μεταλλείων και Δημοσίων Εργων) in 1909, which was in turn absorbed into Greek Enterprises S.A. (Α.Ε. Επιχειρήσεων εν Ελλάδι) in 1913. In 1921, the mine was acquired by Alexiou, Antonakopoulos & Co. (Π. Αλεξίου, Ν. Αντωνακόπουλος και Σία), which in 1928 together with Greek Enterprises S.A., established the final company that actively extracted Sulphur in Milos, the Milos Sulphur Mines S.A. (Θειωρυχεία Μήλου Α.E.). Whilst the mine has passed into several further hands since 1958, when the mine closed, none of these owners resumed regular mining activity.

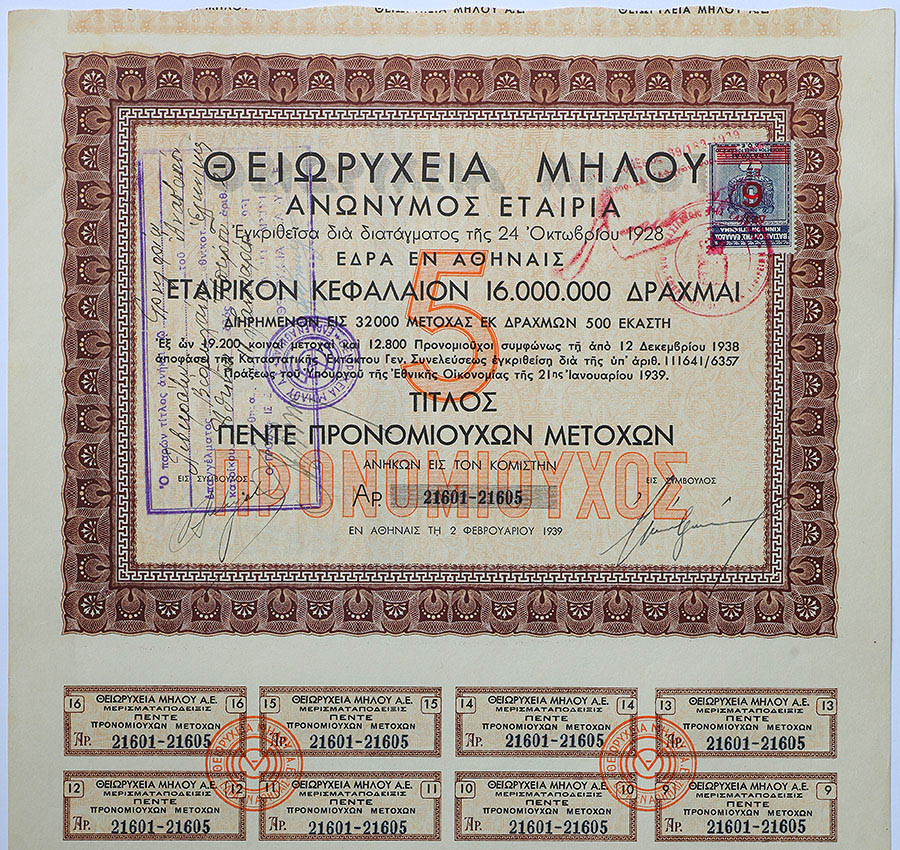

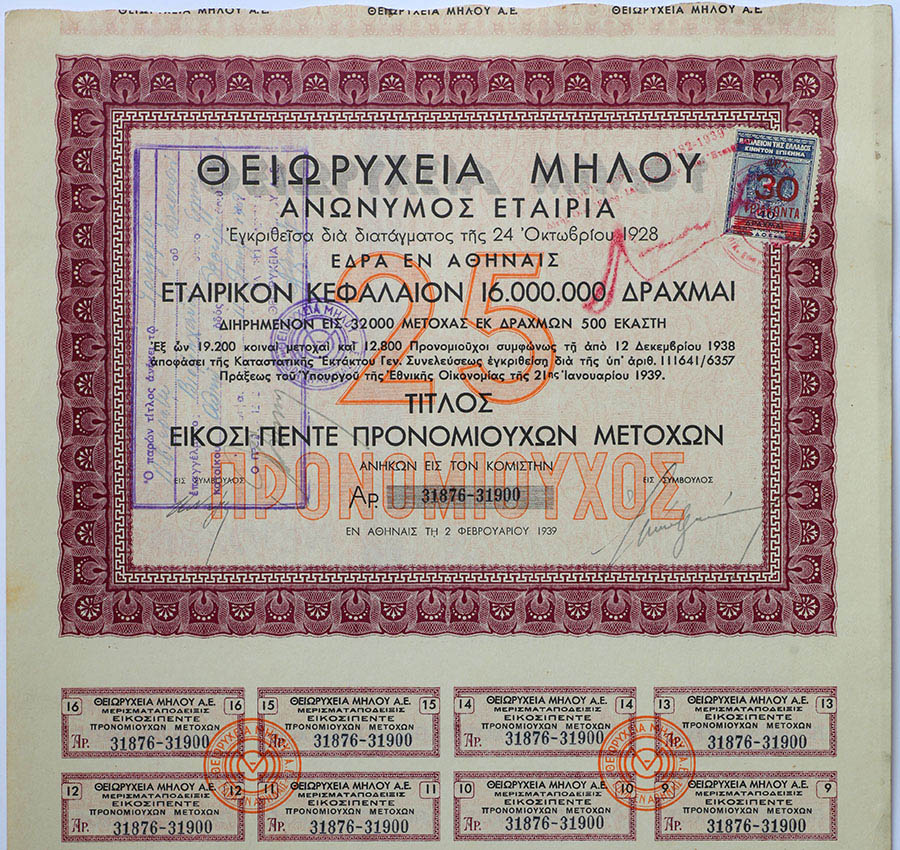

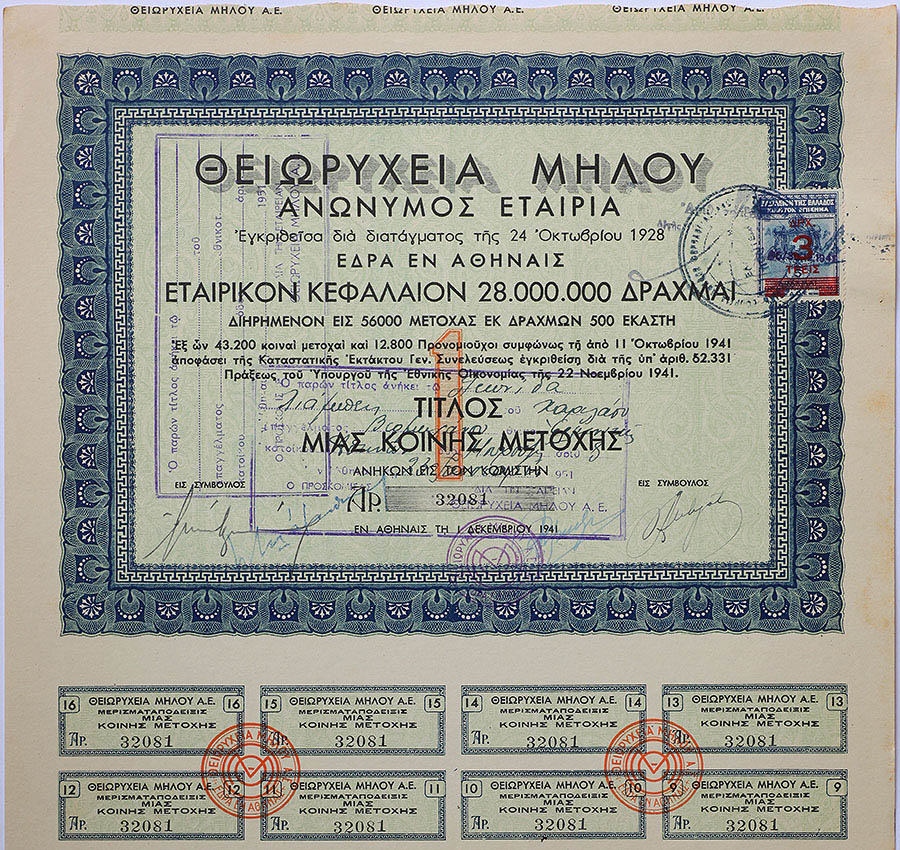

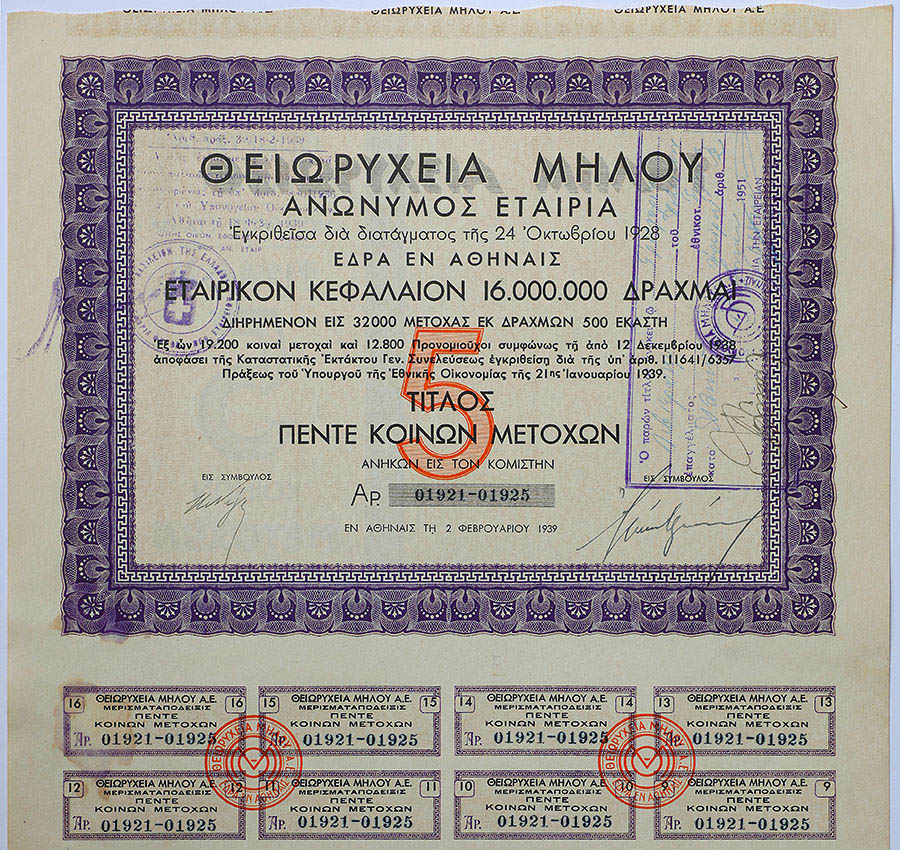

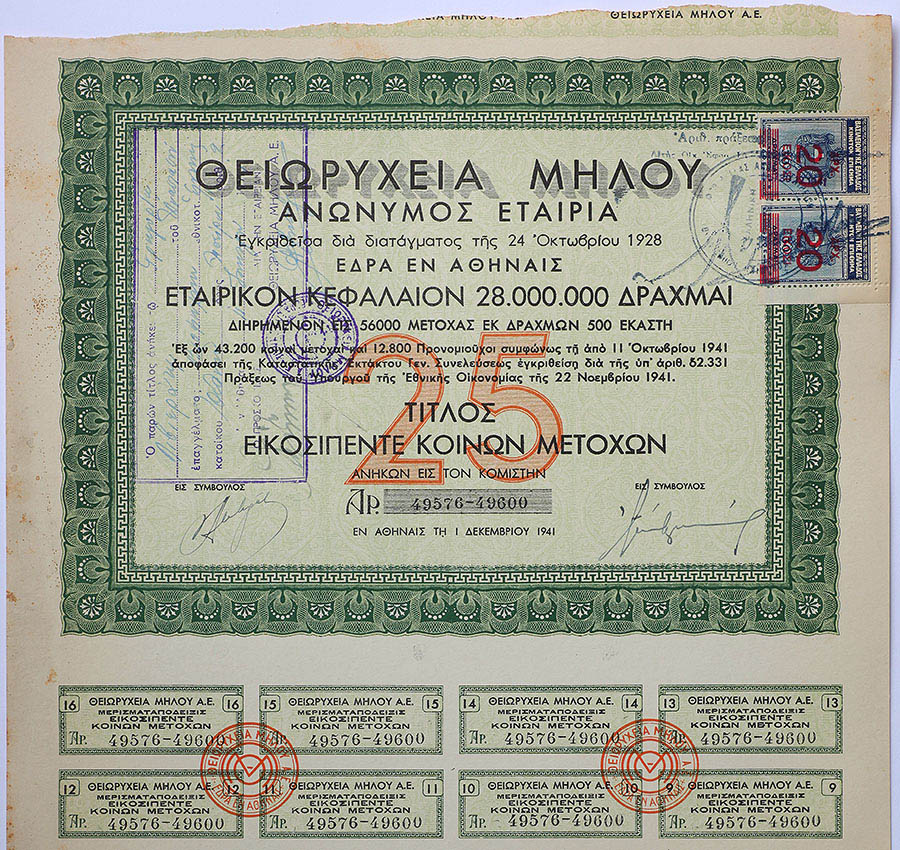

The following images show share certificates from the Milos Sulphur Mines S.A. company with some of the associated dividend coupons attached at the bottom. Certificates of 100 shares were also issued, at least in 1942. If you have other share certificates from this company or any of the earlier owners, please contact me so that images thereof can be added to the website.

|

|

|

|

Milos Sulphur Mines S.A. - 1 Ordinary Share |

Milos Sulphur Mines S.A. - 5 Ordinary Shares |

Milos Sulphur Mines S.A. - 25 Ordinary Shares |

Mine Layout

Maps are available showing the layout of the mine (Milos Sulphur Mines, Gregores Belivanakes, 2004; Annexes). The main sulphur bodies from which ore was extracted were located underground and accessed by horizontally driven tunnels (adits). The mine adits contained narrow-gauge rails on which minecarts were moved by hand. The rails further connected the mine adits to the main processing facilities and also to the dock facilities for loading the sulphur onto boats. One adit entered south of the administration buildings and connected to possibly the first major underground deposit mined in the valley, since an early ore mill was constructed at its exit. The main bodies of sulphur mined by Milos Sulphur Mines S.A. were however located in the hillsides flanking the valley several hundred meters west of the main mine buildings and were linked to the processing plant area by the main No.1 (or "Ace") adit. The rails connecting processing plant and dock crossed a small stone bridge as they progressed towards the dock which had a crane for lifting ore onto waiting ships. A further bridge connected the auxiliary buildings to the processing facility at the height of the construction bureau.

Todays mine layout largely derives from a period of construction starting in the late 1930s, when a major modernization program was implemented (partially financed by the issuing of more shares (see above)), including the construction of the main hill-side sulphur processing plant which forms the most prominent part of the ruins today (note: some images of the hillside plant are found in the Belivanakes book, dated to as early as 1920. If this dating is correct, it would suggest that the plant may have been modernized using already existing buildings.) . Further auxiliary buildings housing offices, accommodation, laboratories, workshops and the generator were constructed during this period. The plant has a twin-railed sloped incline for transporting ore from a storage bunker at its base to the top of the processing facility. From here the ore was passed through the processing facility and was crushed before sulphur was extracted by heating followed by separation by sieving and flotation processes, as shall be explained in more detail in the following section.

|

Paliorema valley with mine and processing facilities |

Main sulphur processing plant |

Remains of dock facility |

|

View from valley with track of powered incline in front of processing buildings |

Manpower-operated tipable minecart for ore transport from mine to processing facilities and from the latter to the dock |

Sulphur Processing Plant (Svoronos Method)

At Paliorema, some of the sulphur ore obtained was also processed on site, allowing shipment of either ore, or relatively pure sulphur from the site. Initially, sulphur was extracted from crushed ore by heating the latter in a set of kilns. In the kiln, the sulphur was melted and a proportion of it would manage to flow to the bottom of the kiln where it could be collected. Various forms of this process were used at Paliorema, progressing from the Calcarone process to the Doppioni, and finally Gatto-Gill process (although the 1957 Krupp Report suggests that the Calcarone process was still being used in 1939). The Calcarone process generally involves a large kiln with a sloping base with a grid at the lower side. After igniting the sulphur, the top of the kiln was covered with slag, thus reducing access of oxygen and reducing combustion. As the sulphur burns, a proportion melts and drains to the bottom of the kiln. Pollution is significant, yet reduced to some extent compared to the most basic open-topped oven types (Calcarella (probably not used at Paliorema)) but the process takes 1-3 months (depending on size). Combustion of significant amounts of the sulphur is a further disadvantage of the process.

The Doppioni process involves the use of two connected chambers. One vessel is generally heated using e.g. wood or coke and this causes melting and finally (above 410'C) evaporation of sulphur. The sulphur gas passes through a pipe into the second chamber in which it cools and condenses, allowing it to be collected in relatively pure form. The basic principle of cooling sulphurous gases to achieve condensation can be seen in a simple form today at Kawah Ijen sulphur mine, where fumarolic gases are cooled in pipes with liquid sulphur being collected at the bottom of them.

In the Gatto-Gill process, a series of chambers is used with the exhaust gases flowing to adjacent chambers which are thereby preheated and finally catch fire. The process is similar to the Calcarone process insofar as sulphur is collected at the base of the kiln, which again has a sloping base. The kilns are however smaller and the process can run continuously if an array of kilns is used.

Even with the most advanced Gatto-Gill process, recovery of only about 35% of the sulphur within the ore at Paliorema could be achieved, compared to 65% in sicilian deposits using the same method (Ekonomopoulos, 1952, Ind. Engineer. Chem. 44(1), p.105-106). This was a result of the properties of the locally mined tuffaceous ore which tends to break down in the smelters once the sulphur is fluidized and thus obstructs passage of sulphur to the base of the kiln. Further, the process also results in the release of noxious sulphurous gases, particularly sulphur dioxide. These had a debilitating effect on the early miners at Paliorema with many dying of lung conditions, in particular consumption (pulmonary tuberculosis).

The processing plant which lies in ruins today was constructed in the late 1930s and briefly used in 1940 before disruption by the war. Operations resumed in 1953 and the plant continued to operate until 1958, producing about 15000 Tonnes of Sulphur in this period. The plant was constructed for processing sulphur-containing ore by the Svoronos process.

In 1927, the greek inventor Jason J. Svoronos applied for a greek national patent (GR1560) for a novel form of sulphur extraction from ore. An equivalent patent was applied for in germany in 1937 (DE703159). The process no longer relies on combustion of sulphur and yields as much as 90% of the sulphur entrapped in ores. In the process, the sulphur-containing ore is crushed and then basically heated in a solution at a temperature of about 120'C. The sulphur melts at this temperature and upon cooling, small lumps of sulphur form which can be separated by a flotation process. Looking at the mine layout at Paliorema (based on technical diagram of Hungarian Stefka, drafted in 1966 (Annex 6 in "Milos Sulphur Mines")), it is however evident that 2 heating steps were employed, at least at some stage during the facilities operation. This is in line with the teachings of a slightly more recent patent by Svoronos (DE864232, patented 27.07.1938; Based on greek patent applications filed on 26.07.1937 and 22.01.1938).

DE864232 explains the process in some detail. In a first step, the ore is ground to the size of a hazelnut and then loaded into a pressure cooker, in which it is heated to a temperature of at least 120'C for a time sufficient to melt the sulphur in the ore (the cooker may alternatively contain a solution that doesn't boil until at above 120'C at atmospheric pressure, in which case the vessel would not need to be pressurized). During heating, the mixture is agitated to further break up the ore and to allow the molten sulphur to start to form small globules (granule size can be influenced by speed of agitation). The mixture is then allowed to cool, whilst agitation continues. This ensures that the sulphur globules remain small and solidify to granules with a diammeter of less than 1 mm. The material is sieved to remove any rock fragments over 1 mm in size. At the end of this first step, one thus obtains a mixture of sulphur granules and small fragments of the tuffaceous rock in which the sulphur was embedded.

In the second step, the sulphur must be removed from the fine rock fragments. The mixture from step 1 is again heated in a pressure cooker to melt the sulphur, this time with gentle or no agitation. In the presence of higher sulphur concentrations and without significant agitation, molten sulphur forms larger globules. After cooling, one obtains a mixture wherein the rock fragments remain at or below the cut-off size of the sieving process at the end of stage 1 (e.g. less than 1 mm), whilst the sulphur granules are now significantly larger. A further sieving step can now be employed, wherein the sulphur is retained by the sieve and the small rock fragments pass through it and are thus removed. Alternatively to step 2, a flotation-separation process is suggested (as in the earlier patent).

The process actually employed in the processing plant at Paliorema is based on the above patent, yet based on documents from the German Krupp company, which visited the mine shortly before its closure and documented the process, some modifications appear to have been in place. The text of the report suggests that a single pressure cooker was used and no flotation step was employed. A purifying autoclave in a building adjoining the plant was then used. This requires further investigation. The plan of the plant (according to Stefka) and a greek translation of the text of the Krupp Report are found in the book "Milos Sulphur Mines" by G. Belivanakes. It is certainly puzzling that the upper silo appears to have been converted to accommodation - there is no connection from elevator to silo and several bedframes are found in the chamber that houses the silo according to the plan of the plant. It is however possible that these changes were made after closure of the plant.

The processing equipment was spacially arranged in the plant as follows (based on Stefka Annex). After being transported up the incline, the ore passed through a sorting and crushing process in the rooms nearest the incline, was then elevated to the top of the middle row of rooms in which it was heated to extract sulphur and again subjected to size-sorting processes, following which it was lifted by conveyor belt to a silo above the final set of rooms containing a second heating apparatus for further separation of sulphur from the rock followed by size-sorting / flotation-separation to isolate the sulphur. Further buildings located on the valley floor below the main plant were presumably for storage or further refining steps. The two Gilardoni centrifugal hammer-mills were for powdering the product before packaging for shipping and were only installed shortly before closure of the plant. In particular, on the diagram of the plant (Stefka) it appears that whilst two sequential heating steps are employed, each followed by sieving steps, the second sieving step is followed by a flotation step (i.e. the two alternatives for step 2 in the DE864232 patent appear to have been combined to achieve improved purification).

|

Top of elevator |

Former silo at top of elevator. Rusting bedframes suggest it was eventually put to alternative use. |

|

Top of conveyor belt taking material to silo of autoclave |

Rails leading from silo at top of conveyor belt (Function unknown) |

|

Main boiler room. Used for generating heat for processing boiler and autoclave. Boiler is encased in brick wall bottom right. |

Remaining bottom section of chimney |

Oil-burner powering main boiler |

|

Storage bunker above sieving / flotation machinery |

Sieving / flotation machinery for separation of sulfur from remaining rock fragments |

Base of sieving / flotation machinery |

|

Storage tanks in processing building at base of hillside processing plant |

Gilardoni centrifugal hammer-mill |

Mine with bridge and small constructors bureau in foreground |

Generator Shed, Workshops, Laboratory & Administration

On the southern side of the Paliorema valley are several auxiliary buildings. Nearest the sea is the largest concrete building, the combined office / accommodation block. Moving inland one sees a number of buildings for storage, housing the main diesel generator and machine workshop, and further blacksmith and carpentry facilities. Furthest inland is a workers accommodation block. The accommodation and office blocks were constructed shortly after WW2.

|

View over auxiliary buildings from top of powered incline of processing plant. |

Workers accommodation block |

|

Main diesel generator for mine |

Mobile generator / compressor (?) for driving mine machinery |

Maintenance building with old ventilation fan |

|

Workshop |

Workshop |

Accommodation, Canteen & Office Block

The mine lies a distance from the nearest villages, so miners generally remained at the site overnight. In the early days of the mine, miners often slept in tiny caves, after WW2, the concrete accommodation blocks were constructed. Apparently, the miners would have been preferred to be transported by bus to their home villages, the company however wanted them to remain on site.

The block nearest to the sea also had offices and a simple canteen where food could be purchased using tokens. These tokens were generally issued in place of part of the salary, especially when the mine was short of cash. Aluminium tokens of 50 lepta, 1, 2, 5 and 10 drachmen were issued with a design including the Milos Sulphur Mine name and symbol. Simple 2 (copper) and 5 (aluminium) lepta tokens, with the number 2 or 5 thereon, but no further text or other features, were also used.

|

|

|

Tokens for purchasing food and drinks from the mine canteen (Text: Milos Sulphur Mines A.E. - Headquarters in Athens) |

|

|

Accommodation / Office Building |

|

|

|

Inside first floor of office / accommodation building |

|

Underground

The hillsides containing the sulphur deposits contain a large number of horizontal tunnels (adits) accessing the actual underground deposits. The main adit in the Paliorema valley was No.1 ("Ace") adit. This connected the main sulphur bodies to the processing plant. Following a landslide the remains of the entrance and adjacent storehouse have now been buried. Mining was initially performed using simple tools but later pneumatic drills were employed. The use of explosives was also common and these were stored away from the main mine buildings for safety reasons.

Several further tunnels can be found in the vicinity of the dock facilities. The function of a short tunnel under the rails to the dock in unclear. A longer tunnel (No. 0) adjacent to the location of the crane may have been used for storing mine carts adjacent to the dock.

Conditions underground were harsh. Due to residual hydrothermal activity and exothermic reactions occurring as the sulphur-bearing ore was exposed during mine operations, temperatures of over 40'C were reached in certain parts of the mine. Sulphur dust mobilized during drilling operations also severely affected the lungs of workers. Following a number of court cases brought by miners, the company worked on improving ventilation in the mine during its latter years of operation. Mine adit No.2 was used for ventilation and had a large fan installed at its entrance. Several further ventilators were in use and compressed air was also pumped into the mine to improve air quality, in addition to driving the pneumatic drills.

|

|

Tunnel No. 0 by dock facility |

|

|

Gas-mask for protection against sulfurous gases, Milos Mining Museum |

Ventilator for use in mine, Milos Mining Museum |

Mining tools, Milos Mining Museum. Small pneumatic drill is visible. |

Additional Features

|

Support for pipes through which seawater was pumped to water reservoir above sulfur-processing plant |